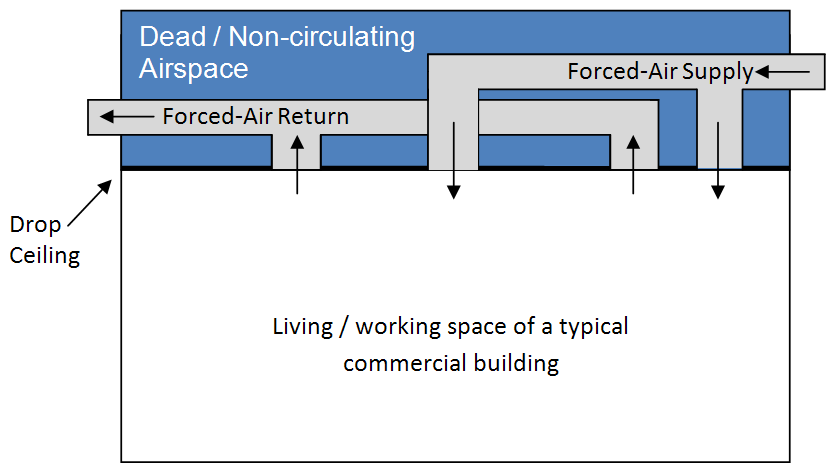

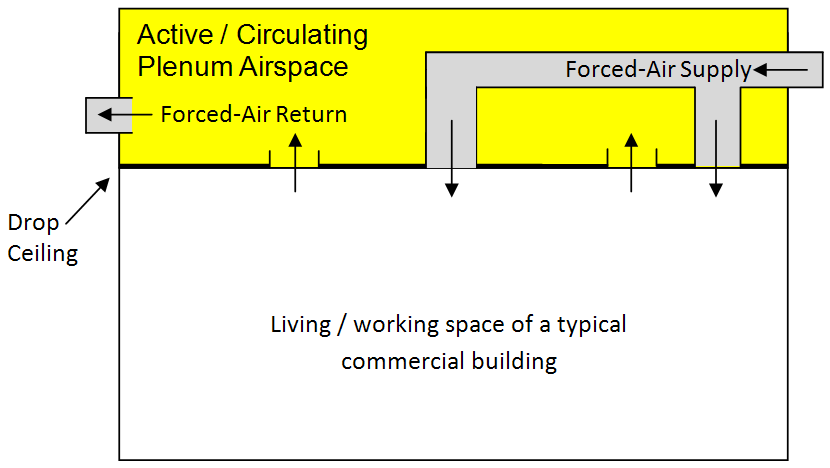

Plenum cable is a cable that is laid in the plenum spaces of buildings. A plenum space is a part of a building that can facilitate air circulation for heating and air conditioning systems, by providing pathways for either heated/conditioned or return airflows, usually at greater than atmospheric pressure. Space between the structural floor and the dropped ceiling, or under a raised floor is typically considered plenum; however, some drop-ceiling designs create a tight seal that does not allow for airflow and therefore may not be considered a plenum air-handling space.

In the United States, plastics used in the construction of plenum cable are regulated under the National Fire Protection Association standard NFPA 90A: Standard for the Installation of Air Conditioning and Ventilating Systems. All materials intended for use on wire and cables to be placed in plenum spaces are designed to meet rigorous fire safety test standards in accordance with NFPA 262 and outlined in NFPA 90A.

Plenum cable is jacketed with a fire-retardant plastic jacket of either a low-smoke polyvinyl chloride (

PVC) or a fluorinated ethylene polymer (FEP). Polyolefin formulations.

Plenum-rated and riser-rated cables are restricted to only allow certain chemicals for manufacture of the wire insulation and cable sheath. Typically this results in reduced flexibility of plastic cables, making it stiff and hard to bend. The bend radius may also be increased, and tight bends can potentially crack or tear the insulation and sheathing.

Alternative cable jackets are PVC or LSZH popularly used outside of the North American region.